Details emerge of Genesee & Wyoming plans for first test of autonomous container equipment

Test Track #TestTrack

A prototype of the Parallel Systems autonomous container rail system tests in Southern California. Parallel Systems

A prototype of the Parallel Systems autonomous container rail system tests in Southern California. Parallel Systems

WASHINGTON – A pair of Genesee & Wyoming short lines have detailed their plans to test Parallel Systems’ autonomous, battery-electric intermodal cars in an application filed with the Federal Railroad Administration.

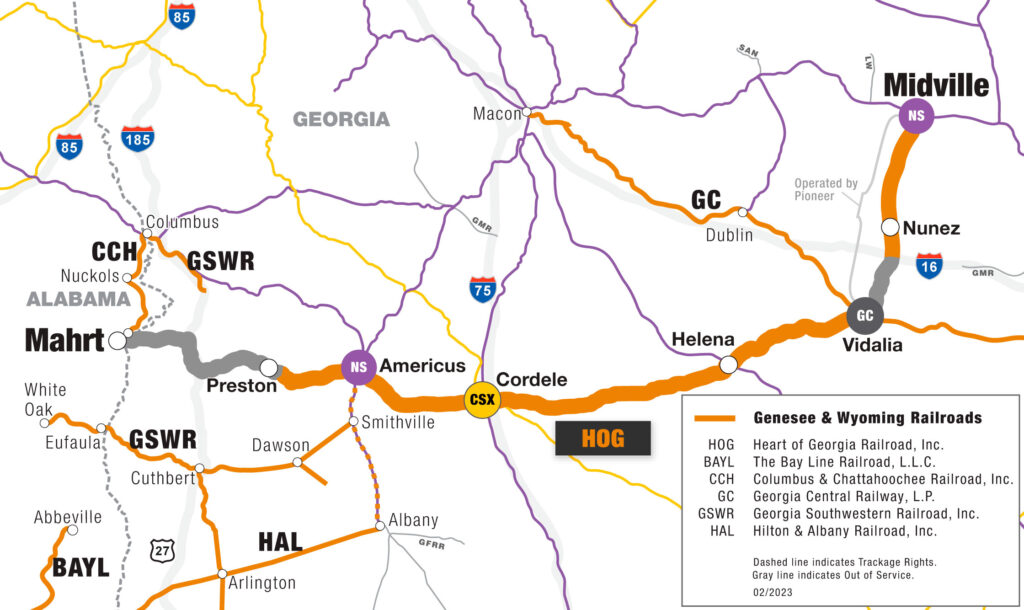

Last month G&W and Parallel announced that they were seeking FRA permission to conduct the tests next year on the Heart of Georgia Railroad and Georgia Central Railway [see “Genesee & Wyoming short lines seek permission for autonomous container car tests,” News Wire, Aug. 10, 2023]. But they did not release the application, which is now publicly available.

The 65-page document, titled “Application For Temporary Suspension Of Certain Rules And Exemption From Safety Appliance Standards For The Testing Of Novel Freight Rail Technology,” outlines the proposal for progressively more complex tests of Parallel Systems’ innovative equipment.

“The first priority of each phase of the Program is to assure safety of railroad employees, other persons and property, and the general public along the railroad lines that will be used for the Program,” according to the application.

Parallel Systems autonomous equipment is outlined in G&W’s test application with the Federal Railroad Administration.

Parallel Systems autonomous equipment is outlined in G&W’s test application with the Federal Railroad Administration.

Parallel’s battery-electric cars – which can run alone or together as an autonomous platoon – can each carry a single 40-foot container weighing up to 65,000 pounds. They can operate at up to 25 mph and tackle grades as steep as 3%. “These design features are intended to help railroads better compete against trucks in the short-haul movement of intermodal containers rather than to replace conventional railroad rolling stock,” the application says.

The tests aim to evaluate the three primary components of the Parallel system: The autonomous vehicles themselves, the user terminals that allow people to control the equipment, and the computer servers that send data between the vehicles and the user terminals.

The cars, which consist of two bogies connected by a spanning structure, have independent mechanical and parking brakes and the electromechanical subsystems required to move, stop, and park without a human operator on the vehicle. Cameras and sensors on board the equipment monitor its performance.

The server software enforces safety rules, including the speed, direction, and planned stopping location for each vehicle. If a car detects a hazardous condition, the vehicle control system independently brings it to a stop and applies the parking brake without direction from the server.

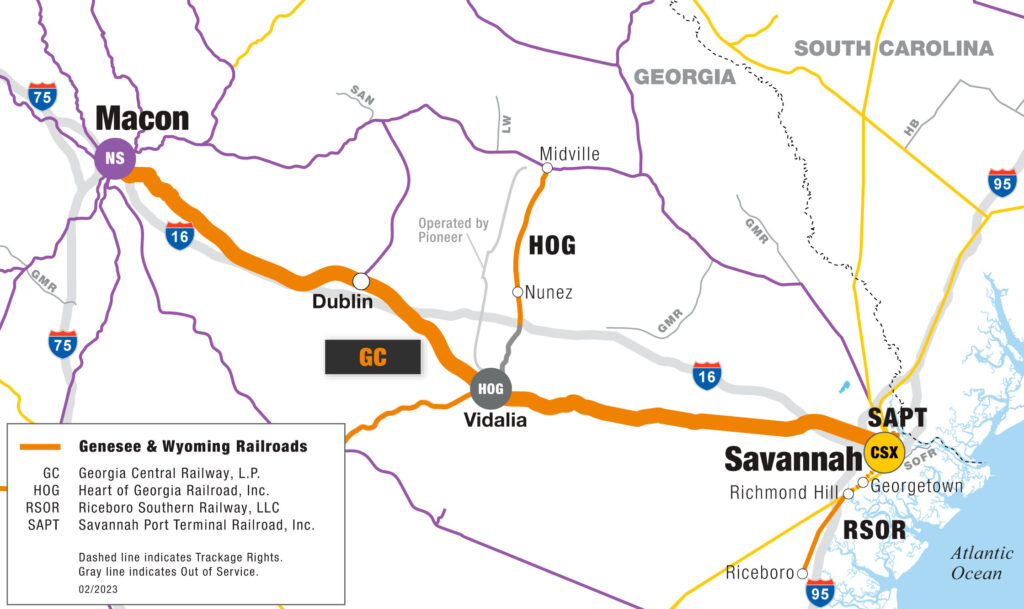

The test program will be conducted on portions of the Heart of Georgia from milepost 663, just east of Cordele, Ga., to the connection with Georgia Central at milepost 577.8 in Vidalia, Ga., and then on Georgia Central from milepost 577.8 to milepost 503 near Pooler, Ga.

The first phase will involve a 2-mile section of track on the Heart of Georgia that’s free of grade crossings. The test track will be severed from the rest of the railroad by removing the rails at both ends.

Phase two will be expanded to a 30-mile section of the Heart of Georgia. Testing will be performed under track warrants with no other rail operations present and all public grade crossings protected by flaggers.

Phases three and four will operate over an 84-mile section of track between Vidalia and Cordele on the Heart of Georgia and will include tests under track warrant control as well as in yard limits. The HOG-Norfolk Southern diamond at milepost 610.7 will be protected by derails during the tests.

The fifth phase of testing will incorporate updated hardware and will involve the first use of containers on the Parallel cars on a 30-mile section of the Heart of Georgia, between Vidalia and just east of Helena, Ga.

Testing ramps up in phases six and seven and will operate over a 160-mile section of the Heart of Georgia and Georgia Central.

“Phase Six operations are intended to evaluate the operational effectiveness of the System in field conditions operating intermixed with conventional rail service as governed by the railroad dispatchers and operating rules. Containers containing test weights will be transported on the Vehicle,” the application says.

In this phase, grade crossings will rely on regular protection without flaggers. But as in all phases a vehicle supervisor with a stop control will monitor all operations.

The final phase will evaluate platooning with loaded containers. “A limited number of revenue containers may be moved in Phase Seven, allowing for an assessment of damage-in-transit, to compare this unique new technology with direct truck competition. Otherwise, containers will carry test load weights,” the application says.

Testing will be conducted with loads and empties, in all sorts of weather conditions, and at night, daytime, and dawn and dusk. The pilot aims to assess the reliability of the system, its compatibility with existing operations, and the costs of operation.

“The details of each phase of the Program will assure continuation of safe rail freight operations on HOG and GC without disruption to the customers on both railroads. The last two phases of the Program, as explained in the Safety Plan, will involve mixed use of Vehicle operations and conventional freight train operations, under separate authorities granted by the dispatchers of each railroad. The ability of the System to safely and reliably operate concurrently with conventional rail freight services is a very important element to be demonstrated as part of the Program.”

The Parallel Systems cars lack couplers and are not compatible with conventional railroad equipment. They can operate as a platoon by having bumpers at each end of the cars touch while in motion.

“The automatic platooning concept allows Vehicles to run in very close proximity and function as one unit without physically coupling to each other. While the Vehicles will push on each other using the bumper interface that transmits compressive (buff) forces, they will not be positively attached and will not transmit tensile (draft) forces. No coupling mechanism is actuated in the process of forming the platoon, one Vehicle simply moves towards the other Vehicle until the bumper senses contact force,” the application explains. “In the platooned configuration, the leading Vehicle operates according to commands from the Server and monitors the track ahead using its perception system. Each following Vehicle controls its motion (independently communicating with the Server) to maintain a minimum force measurement at its leading bumper. In this way, all Vehicles in the platoon remain in contact, traveling at the same speed as the lead Vehicle.”

Last year G&W railroad managers held discussions with employees, rail labor union officials, first responders, and community leaders along the proposed test routes, as well as with state legislators, members of Congress, and senior officials from the Georgia Department of Transportation.

The application asks the FRA to temporarily waive a slew of current regulations, from rail operating practices and locomotive safety standards to safety appliance standards and brake system safety regulations.

“The Program offers an important and unique opportunity to allow smaller freight railroads like GC and HOG to meaningfully compete in the short-haul transportation of containers. These local markets, usually within 500 miles between origin and destination, are typically not served by freight railroads today due to uncompetitive economics driven by the current advantages of truck transport in short distance corridors, such as rapid cycle times and less circuity. The new technology provided by the System will allow for the rail movement of containers in a more competitive manner, both in frequency of service and in total costs,” the application says.

Parallel Systems, based in Los Angeles, was founded by former SpaceX, Google, and Tesla engineers.

Parallel Systems employees gather around a battery electric bogie at the company’s Los Angeles headquarters. Parallel Systems

Parallel Systems employees gather around a battery electric bogie at the company’s Los Angeles headquarters. Parallel Systems